Fluid Bed Processor

Processing Modules

Dryer: Warm Air Is Blown Through A Perforated Distributor To Rapidly And Gently Dry Materials Until The Required Residual Moisture Content Is Reached. Moisture Evaporated From The Product Is Exhausted With The Drying Air, Providing Very Short Processing Times.

Precision Granulator: A Novel Granulation Process, A Rotating High Velocity Air Stream Is Established In The Central Agglomeration Tube. Particles Are Picked Up At The Base Of The Tube And Accelerated By The Air Stream. The Particles Come Into Contact With Liquid Droplets Produced From The Spray Nozzle At The Base Of The Tube. The Relative Velocity Of The Air, Liquid Droplets And Particles Are High, So Wetting Is Efficient And Drying Begins Almost Immediately. Most Of The Feed Material Is In The Outer “Holding Area,” Where The Gas Velocity Is Very Low. Attrition Is Greatly Reduced. The Gas Humidity Is Also Low In The Holding Area So The Material Is Dry Not Sticky. Individual Particles May Make Repeated Cycles (Typically From 10 To 1000) Through The Tube, Allowing Very Large Agglomerates To Be Built Up.

Top Spray Granulator: Offering Granulation And Drying In A Single-Pot Process, The Top Spray Granulator Agglomerates Finer Particles Into Larger, Free Flowing Granulates. Ingredients Are Mixed And Pre-Heated By An Upward Flow Of Heated Air. Granulation Occurs By Spraying Liquid Into The Fluidized Powder. The Granules Are Subsequently Dried With Heated Air. The Top Spray Granulator Can Also Be Used For Top Spray Coating, Layering From Liquid, And Instantizing.

Spray Dryer Granulator: With Batch Or Continuous Discharge Available In Continuous Mode, The Spray Dryer Granulator Transforms Suspensions Or Solutions Into Dry, Free-Flowing, Dustless Granules. A Suspension Or Solution Of The Substance To Be Dried Is Sprayed Onto Warm Air, Simultaneously Drying And Agglomerating The Product. The Product Is Discharged At A Controlled Rate To Maintain An Optimum Bed Height. Special Features Include Easy Scale-Up And A Small Footprint.

Precision-Coater: This Multi-Functional Fluid Bed Processor Can Be Used To Make Pellets By Layering The Active Material Onto An Inert Core. Offering High Spray Rates For Short Processes, Non-Pareil Starter Pellets Are Sprayed With A Solution Or Suspension Of The Active Material And Dried Simultaneously.

Steel Fluid Bed Dryer

Fluid Bed Dryer Is Designed To Introduce The Hot Air Stream At The Base Of The Product Container, Which Is Filled With The Material. Induced Drought Is Created By Means Of Blower And Fresh Air Is Sucked In To The Unit. The Fresh Air Is Heated By Means Of Electrical Heaters Or Steam Or Thermic Fluid Heaters. This Hot Air Stream Expands The Bed Of Material At Certain Velocity & Creating Turbulance In The Product. The Phenomenon Is Known As Fluidisation And Offer Conditions, Which Are Almost Ideal For Drying. Fluidisation Produces Full Agitation Of Solid Particles And Since Each Particle Gets Surrounded By Hot Air Heat Transfer Is Extremely High And Uniform. The Product Is Dried Fast Without Appreciable Loss Of Heat. Filter Bags Prevent Particles Escaping From The Dryer.

And Capacity Of Fluid Bed Dryers Offered By Us Is Available In The Range Of 30 To 500 Kg, With Steam Heating, Electrical Heating And Thermal Heating Facility. Electrically/Steam And Thermic Fluid Heated In Which General Structure Is Made Out Of Mild Steel And Painted In Standard Model. Made Out Of S.S.304 Quality Material And Polished To The Matt Finished In Gmp Model. The Contact Parts Such As Product Container And Retarding Chamber Are Made Out Of S.S.304/5.S.316 Quality Material, Provided With Non-Flammable Blower Motor, (Flame-Proof Motor Provided On Demand) Suitable To Dry Wet Material.

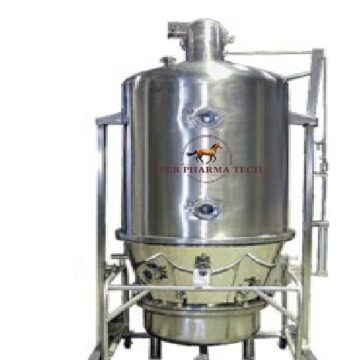

Stainless Steel Silver Fluid Bed Dryer

Fluid Bed Dryer Is Designed To Introduce The Hot Air Stream At The Base Of The Product Container, Which Is Filled With The Material. Induced Drought Is Created By Means Of Blower And Fresh Air Is Sucked In To The Unit. The Fresh Air Is Heated By Means Of Electrical Heaters Or Steam Or Thermic Fluid Heaters. This Hot Air Stream Expands The Bed Of Material At Certain Velocity & Creating Turbulance In The Product. The Phenomenon Is Known As Fluidisation And Offer Conditions, Which Are Almost Ideal For Drying. Fluidisation Produces Full Agitation Of Solid Particles And Since Each Particle Gets Surrounded By Hot Air Heat Transfer Is Extremely High And Uniform. The Product Is Dried Fast Without Appreciable Loss Of Heat. Filter Bags Prevent Particles Escaping From The Dryer.

And Capacity Of Fluid Bed Dryers Offered By Us Is Available In The Range Of 30 To 500 Kg, With Steam Heating, Electrical Heating And Thermal Heating Facility. Electrically/Steam And Thermic Fluid Heated In Which General Structure Is Made Out Of Mild Steel And Painted In Standard Model. Made Out Of S.S.304 Quality Material And Polished To The Matt Finished In Gmp Model. The Contact Parts Such As Product Container And Retarding Chamber Are Made Out Of S.S.304/5.S.316 Quality Material, Provided With Non-Flammable Blower Motor, (Flame-Proof Motor Provided On Demand) Suitable To Dry Wet Material.

Semi-Automatic Fluid Bed Dryer Processor

Fluid Bed Dryer Is Designed To Introduce The Hot Air Stream At The Base Of The Product Container, Which Is Filled With The Material. Induced Drought Is Created By Means Of Blower And Fresh Air Is Sucked In To The Unit. The Fresh Air Is Heated By Means Of Electrical Heaters Or Steam Or Thermic Fluid Heaters. This Hot Air Stream Expands The Bed Of Material At Certain Velocity & Creating Turbulance In The Product. The Phenomenon Is Known As Fluidisation And Offer Conditions, Which Are Almost Ideal For Drying. Fluidisation Produces Full Agitation Of Solid Particles And Since Each Particle Gets Surrounded By Hot Air Heat Transfer Is Extremely High And Uniform. The Product Is Dried Fast Without Appreciable Loss Of Heat. Filter Bags Prevent Particles Escaping From The Dryer.

And Capacity Of Fluid Bed Dryers Offered By Us Is Available In The Range Of 30 To 500 Kg, With Steam Heating, Electrical Heating And Thermal Heating Facility. Electrically/Steam And Thermic Fluid Heated In Which General Structure Is Made Out Of Mild Steel And Painted In Standard Model. Made Out Of S.S.304 Quality Material And Polished To The Matt Finished In Gmp Model. The Contact Parts Such As Product Container And Retarding Chamber Are Made Out Of S.S.304/5.S.316 Quality Material, Provided With Non-Flammable Blower Motor, (Flame-Proof Motor Provided On Demand) Suitable To Dry Wet Material.

Manual Fluid Bed Dryers

Fluid Bed Dryer Is Designed To Introduce The Hot Air Stream At The Base Of The Product Container, Which Is Filled With The Material. Induced Drought Is Created By Means Of Blower And Fresh Air Is Sucked In To The Unit. The Fresh Air Is Heated By Means Of Electrical Heaters Or Steam Or Thermic Fluid Heaters. This Hot Air Stream Expands The Bed Of Material At Certain Velocity & Creating Turbulance In The Product. The Phenomenon Is Known As Fluidisation And Offer Conditions, Which Are Almost Ideal For Drying. Fluidisation Produces Full Agitation Of Solid Particles And Since Each Particle Gets Surrounded By Hot Air Heat Transfer Is Extremely High And Uniform. The Product Is Dried Fast Without Appreciable Loss Of Heat. Filter Bags Prevent Particles Escaping From The Dryer.

And Capacity Of Fluid Bed Dryers Offered By Us Is Available In The Range Of 30 To 500 Kg, With Steam Heating, Electrical Heating And Thermal Heating Facility. Electrically/Steam And Thermic Fluid Heated In Which General Structure Is Made Out Of Mild Steel And Painted In Standard Model. Made Out Of S.S.304 Quality Material And Polished To The Matt Finished In Gmp Model. The Contact Parts Such As Product Container And Retarding Chamber Are Made Out Of S.S.304/5.S.316 Quality Material, Provided With Non-Flammable Blower Motor, (Flame-Proof Motor Provided On Demand) Suitable To Dry Wet Material.

Industrial Fluid Bed Dryer

Fluid Bed Dryer Is Designed To Introduce The Hot Air Stream At The Base Of The Product Container, Which Is Filled With The Material. Induced Drought Is Created By Means Of Blower And Fresh Air Is Sucked In To The Unit. The Fresh Air Is Heated By Means Of Electrical Heaters Or Steam Or Thermic Fluid Heaters. This Hot Air Stream Expands The Bed Of Material At Certain Velocity & Creating Turbulance In The Product. The Phenomenon Is Known As Fluidisation And Offer Conditions, Which Are Almost Ideal For Drying. Fluidisation Produces Full Agitation Of Solid Particles And Since Each Particle Gets Surrounded By Hot Air Heat Transfer Is Extremely High And Uniform. The Product Is Dried Fast Without Appreciable Loss Of Heat. Filter Bags Prevent Particles Escaping From The Dryer.

And Capacity Of Fluid Bed Dryers Offered By Us Is Available In The Range Of 30 To 500 Kg, With Steam Heating, Electrical Heating And Thermal Heating Facility. Electrically/Steam And Thermic Fluid Heated In Which General Structure Is Made Out Of Mild Steel And Painted In Standard Model. Made Out Of S.S.304 Quality Material And Polished To The Matt Finished In Gmp Model. The Contact Parts Such As Product Container And Retarding Chamber Are Made Out Of S.S.304/5.S.316 Quality Material, Provided With Non-Flammable Blower Motor, (Flame-Proof Motor Provided On Demand) Suitable To Dry Wet Material.

GMP Fluid Bed Dryer

Fluid Bed Dryer Is Designed To Introduce The Hot Air Stream At The Base Of The Product Container, Which Is Filled With The Material. Induced Drought Is Created By Means Of Blower And Fresh Air Is Sucked In To The Unit. The Fresh Air Is Heated By Means Of Electrical Heaters Or Steam Or Thermic Fluid Heaters. This Hot Air Stream Expands The Bed Of Material At Certain Velocity & Creating Turbulance In The Product. The Phenomenon Is Known As Fluidisation And Offer Conditions, Which Are Almost Ideal For Drying. Fluidisation Produces Full Agitation Of Solid Particles And Since Each Particle Gets Surrounded By Hot Air Heat Transfer Is Extremely High And Uniform. The Product Is Dried Fast Without Appreciable Loss Of Heat. Filter Bags Prevent Particles Escaping From The Dryer.

And Capacity Of Fluid Bed Dryers Offered By Us Is Available In The Range Of 30 To 500 Kg, With Steam Heating, Electrical Heating And Thermal Heating Facility. Electrically/Steam And Thermic Fluid Heated In Which General Structure Is Made Out Of Mild Steel And Painted In Standard Model. Made Out Of S.S.304 Quality Material And Polished To The Matt Finished In Gmp Model. The Contact Parts Such As Product Container And Retarding Chamber Are Made Out Of S.S.304/5.S.316 Quality Material, Provided With Non-Flammable Blower Motor, (Flame-Proof Motor Provided On Demand) Suitable To Dry Wet Material.

Fluidized Bed Dryer Pharma Machinery

Fluid Bed Dryer Is Designed To Introduce The Hot Air Stream At The Base Of The Product Container, Which Is Filled With The Material. Induced Drought Is Created By Means Of Blower And Fresh Air Is Sucked In To The Unit. The Fresh Air Is Heated By Means Of Electrical Heaters Or Steam Or Thermic Fluid Heaters. This Hot Air Stream Expands The Bed Of Material At Certain Velocity & Creating Turbulance In The Product. The Phenomenon Is Known As Fluidisation And Offer Conditions, Which Are Almost Ideal For Drying. Fluidisation Produces Full Agitation Of Solid Particles And Since Each Particle Gets Surrounded By Hot Air Heat Transfer Is Extremely High And Uniform. The Product Is Dried Fast Without Appreciable Loss Of Heat. Filter Bags Prevent Particles Escaping From The Dryer.

And Capacity Of Fluid Bed Dryers Offered By Us Is Available In The Range Of 30 To 500 Kg, With Steam Heating, Electrical Heating And Thermal Heating Facility. Electrically/Steam And Thermic Fluid Heated In Which General Structure Is Made Out Of Mild Steel And Painted In Standard Model. Made Out Of S.S.304 Quality Material And Polished To The Matt Finished In Gmp Model. The Contact Parts Such As Product Container And Retarding Chamber Are Made Out Of S.S.304/5.S.316 Quality Material, Provided With Non-Flammable Blower Motor, (Flame-Proof Motor Provided On Demand) Suitable To Dry Wet Material.

Fluid Bed Machine

Fluid Bed Dryer Is Designed To Introduce The Hot Air Stream At The Base Of The Product Container, Which Is Filled With The Material. Induced Drought Is Created By Means Of Blower And Fresh Air Is Sucked In To The Unit. The Fresh Air Is Heated By Means Of Electrical Heaters Or Steam Or Thermic Fluid Heaters. This Hot Air Stream Expands The Bed Of Material At Certain Velocity & Creating Turbulance In The Product. The Phenomenon Is Known As Fluidisation And Offer Conditions, Which Are Almost Ideal For Drying. Fluidisation Produces Full Agitation Of Solid Particles And Since Each Particle Gets Surrounded By Hot Air Heat Transfer Is Extremely High And Uniform. The Product Is Dried Fast Without Appreciable Loss Of Heat. Filter Bags Prevent Particles Escaping From The Dryer.

And Capacity Of Fluid Bed Dryers Offered By Us Is Available In The Range Of 30 To 500 Kg, With Steam Heating, Electrical Heating And Thermal Heating Facility. Electrically/Steam And Thermic Fluid Heated In Which General Structure Is Made Out Of Mild Steel And Painted In Standard Model. Made Out Of S.S.304 Quality Material And Polished To The Matt Finished In Gmp Model. The Contact Parts Such As Product Container And Retarding Chamber Are Made Out Of S.S.304/5.S.316 Quality Material, Provided With Non-Flammable Blower Motor, (Flame-Proof Motor Provided On Demand) Suitable To Dry Wet Material.