Powder Mass Mixer

Special Features

Range Of Models To Suit Working Volume 50,100 & 200 Kgs. At Bulk Density Of 0.50 Gms/Cc.

Compact Design Requires Compa- Ratively Smaller Floor Space.

Single Stirrer With Single Speed For Dry & Wet Mixing.

Thrust Bearing Are Provided To Carry Out Rigid Thrust Load. Specially Design All Moving Parts Provided With Provision Of Easy Lubrication.

Optional Features

Ss316 Product Contact Parts Instead Of Ss304. Variable Speed Drive Or Double Speed Of Stirrer Provided On Extra Cost, If Required. Flameproof Model . Depending On The Product.

Mass Mixer Machine

Special Features

Range Of Models To Suit Working Volume 50,100 & 200 Kgs. At Bulk Density Of 0.50 Gms/Cc.

Compact Design Requires Compa- Ratively Smaller Floor Space.

Single Stirrer With Single Speed For Dry & Wet Mixing.

Thrust Bearing Are Provided To Carry Out Rigid Thrust Load. Specially Design All Moving Parts Provided With Provision Of Easy Lubrication.

Optional Features

Ss316 Product Contact Parts Instead Of Ss304. Variable Speed Drive Or Double Speed Of Stirrer Provided On Extra Cost, If Required. Flameproof Model . Depending On The Product.

Blender Mass Mixer

Special Features

Range Of Models To Suit Working Volume 50,100 & 200 Kgs. At Bulk Density Of 0.50 Gms/Cc.

Compact Design Requires Compa- Ratively Smaller Floor Space.

Single Stirrer With Single Speed For Dry & Wet Mixing.

Thrust Bearing Are Provided To Carry Out Rigid Thrust Load. Specially Design All Moving Parts Provided With Provision Of Easy Lubrication.

Optional Features

Ss316 Product Contact Parts Instead Of Ss304. Variable Speed Drive Or Double Speed Of Stirrer Provided On Extra Cost, If Required. Flameproof Model . Depending On The Product.

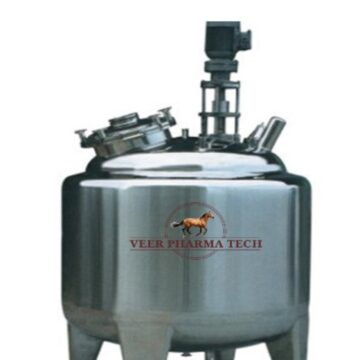

Liquid Mixing Tank Pharma

Liquid Mixing Tank Pharma Are Designed And Crafted To Handle The Unique Demands Of A Variety Of Products. We Offer Several Types Of Impellers Including Completely Customized Designs To Suit Very Unique Applications And Mixing Solutions. We Will Engineer And Design To Your Specifications And Analyze Your Process To Mix Your Liquid Products More Rapidly And Accurately.

Contact Our Responsive Team Today To Learn More About How We Can Meet Your Specific Needs. Also Available In 50 Ltr 50000 & Above. Depending On The Product.

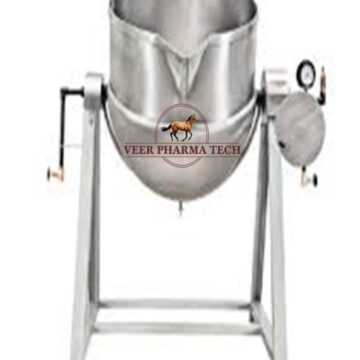

Tilting kettle machine

The Tilting Paste Kettle, Is Designed For Paste Preparation. It Has A Universal Application Resulting In Uniform Melting. This Tank Is Designed To Meet Missing Needs Of Wider Range Of Products Under Varied Operating Conditions In Chemicals, Foods, Cosmetics And Pharmaceutical Industry. The Basic Principle Utilized In The Design Of This Kettle Is The Jacket For Passing Steam In Order To Melt Down The Product To Make Paste. This Kettle Has An Unique Tilting Arrangement For Discharging The Product.

Special Features

Cgmp Construction With Aisi 316 Contact Parts.

Hemispherical Bowl With Either Steam, Electrical Or Oil Heating Options.

Options Available For With / Without Agitator.

Tilting Provided For Ease In Unloading Of Final Products.

Higher Capacity Models Available Without Tilting But With Bottom Outlet.

Capacities Available From 25 Ltrs. To 1500 Ltrs. Depending On The Product.

Paste Kettle Machine

Special Features

Cgmp Construction With Aisi 316 Contact Parts.

Hemispherical Bowl With Either Steam, Electrical Or Oil Heating Options.

Options Available For With / Without Agitator.

Tilting Provided For Ease In Unloading Of Final Products.

Higher Capacity Models Available Without Tilting But With Bottom Outlet.

Capacities Available From 25 Ltrs. To 1500 Ltrs. Depending On The Product.

Kettle Machine

Special Features

Cgmp Construction With Aisi 316 Contact Parts.

Hemispherical Bowl With Either Steam, Electrical Or Oil Heating Options.

Options Available For With / Without Agitator.

Tilting Provided For Ease In Unloading Of Final Products.

Higher Capacity Models Available Without Tilting But With Bottom Outlet.

Capacities Available From 25 Ltrs. To 1500 Ltrs. Depending On The Product.

Jacketed Kettle Machine

The Tilting Paste Kettle, Is Designed For Paste Preparation. It Has A Universal Application Resulting In Uniform Melting. This Tank Is Designed To Meet Missing Needs Of Wider Range Of Products Under Varied Operating Conditions In Chemicals, Foods, Cosmetics And Pharmaceutical Industry. The Basic Principle Utilized In The Design Of This Kettle Is The Jacket For Passing Steam In Order To Melt Down The Product To Make Paste. This Kettle Has An Unique Tilting Arrangement For Discharging The Product.

Special Features

Cgmp Construction With Aisi 316 Contact Parts.

Hemispherical Bowl With Either Steam, Electrical Or Oil Heating Options.

Options Available For With / Without Agitator.

Tilting Provided For Ease In Unloading Of Final Products.

Higher Capacity Models Available Without Tilting But With Bottom Outlet.

Capacities Available From 25 Ltrs. To 1500 Ltrs. Depending On The Product.

Incense Powder Mixing Machine

Incense Powder Mixing Machine Manufactured And Supplied By Us Comprises A U-Shaped Horizontal Trough And A Specially Designed Double Helical Ribbon Agitator Rotating Within. Ribbon Blenders Are Based On A Proven Agitator Construction That Provides A Triple Mixing Action Ensuring Fast, Efficient Blending. The Dimensions And Configuration Of The Ribbons Are Carefully Balanced To Provide A Movement Of Material Within The Container That Avoids Dead Spots And Gives Rapid Product Discharge. An Alternate Design Is The Paddle Agitator. The Paddles Are Positioned To Move The Material In Opposing Lateral Directions As Well As Radially. Paddle Design Is Generally Employed Where Friable Material Are Being Blended, And When Batches As Small As 15% Of The Total Capacity Are Going To Be Mixed In The Blender. Depending On The Product