Jacketed Mixing Tank

Clients Are Also Provided With Optimum Quality Jacketed Tanks That Can Also Be Availed By Them In Customised Sizes And Specifications. These Tanks Are Specially Designed To The Cater To The Requirements Of Various Industries. Known For Their International Standards, These Jacketed Tanks Find Widespread Utilisation In Various Industrial Applications Some Of The Other Details Of Our Products Are As Follows: Ava Le In The Range Of 50 Litre To 10000 Litre Capacities M.S./S.S Jacketed &Ins On With Ss Cladding Direct Top Mounted Stirrer With Top Dish/Without Bottom Dish Different Type Of Stirrer I.E. Propeller/Pedal/Anchor Available Electrical Heating Also Available For Small Vessel Moc S.S 304/316 Bottom Discharge Provided Also Available In 50 Ltr 50000 & Above. Depending On The Product.

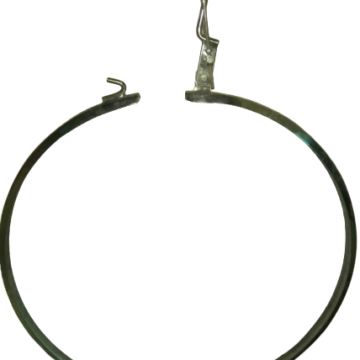

Vibro Sifter Clamp

We Offer Vibro Sifters Clamp Which Are Manufactured Using High Quality Raw Materials. These Products Are Highly Appreciated By Our Clients For Features Such As Durability, Cost-Effectiveness, Corrosion Resistance, Wear & Tear Resistance And High Functionality. Owing To These Features, The Products Offered By Us Finds Widespread Applications In Numerous Sectors Such As Food, Pharmaceuticals Cosmetics And Allied Industries. Depending On The Product.

| Vibro Sifter Clamp Size |

| Vibro Sifter Clamp 12’’ |

| Vibro Sifter Clamp 24’’ |

| Vibro Sifter Clamp 30’’ |

| Vibro Sifter Clamp 36’’ |

| Vibro Sifter Clamp 48’’ |

| Vibro Sifter Clamp 60’’ |

| Vibro Sifter Clamp 72’’ |

Screw Conveyor

Screw Conveyor Specification

Product Description

We Manufacture Precision High Quality Screw Conveyor With U Trough Or Tube. Our Screw Conveyors Find Wide Application In Carrying Bulk Materials.

Salient Features:

Cost Effective Solutions For Conveying Bulk Materials.

Contamination Free Conveying In Closed Environment.

Can Convey Loads In Horizontal Or Inclined Positions.

Well Suited For Controlled/Measured Discharge Conditions.

Multiple Feed Points/Outlets Possible Along The Conveying Path

Applications:

Cost Effective Conveying Of Bulk Materials Like Aggregates, Chemicals, Cereal Grains, Boiler Ash, Wood Chips, Municipal Solid Waste And Other Semi – Solid Materials.

Configurations:

Available In Constructions Of Ms/Ss.

W Shaped Ribbon Blender

Ribbon Blender Machine Manufactured And Supplied By Us Comprises A U-Shaped Horizontal Trough And A Specially Designed Double Helical Ribbon Agitator Rotating Within. Ribbon Blenders Are Based On A Proven Agitator Construction That Provides A Triple Mixing Action Ensuring Fast, Efficient Blending. The Dimensions And Configuration Of The Ribbons Are Carefully Balanced To Provide A Movement Of Material Within The Container That Avoids Dead Spots And Gives Rapid Product Discharge. An Alternate Design Is The Paddle Agitator. The Paddles Are Positioned To Move The Material In Opposing Lateral Directions As Well As Radially. Paddle Design Is Generally Employed Where Friable Material Are Being Blended, And When Batches As Small As 15% Of The Total Capacity Are Going To Be Mixed In The Blender. Depending On The Product

U Shaped Ribbon Blender

Ribbon Blender Machine Manufactured And Supplied By Us Comprises A U-Shaped Horizontal Trough And A Specially Designed Double Helical Ribbon Agitator Rotating Within. Ribbon Blenders Are Based On A Proven Agitator Construction That Provides A Triple Mixing Action Ensuring Fast, Efficient Blending. The Dimensions And Configuration Of The Ribbons Are Carefully Balanced To Provide A Movement Of Material Within The Container That Avoids Dead Spots And Gives Rapid Product Discharge. An Alternate Design Is The Paddle Agitator. The Paddles Are Positioned To Move The Material In Opposing Lateral Directions As Well As Radially. Paddle Design Is Generally Employed Where Friable Material Are Being Blended, And When Batches As Small As 15% Of The Total Capacity Are Going To Be Mixed In The Blender. Depending On The Product

SS Ribbon Blender Mixer Machine

Ribbon Blender Machine Manufactured And Supplied By Us Comprises A U-Shaped Horizontal Trough And A Specially Designed Double Helical Ribbon Agitator Rotating Within. Ribbon Blenders Are Based On A Proven Agitator Construction That Provides A Triple Mixing Action Ensuring Fast, Efficient Blending. The Dimensions And Configuration Of The Ribbons Are Carefully Balanced To Provide A Movement Of Material Within The Container That Avoids Dead Spots And Gives Rapid Product Discharge. An Alternate Design Is The Paddle Agitator. The Paddles Are Positioned To Move The Material In Opposing Lateral Directions As Well As Radially. Paddle Design Is Generally Employed Where Friable Material Are Being Blended, And When Batches As Small As 15% Of The Total Capacity Are Going To Be Mixed In The Blender. Depending On The Product

Single Shaft Ribbon Blender

Ribbon Blender Machine Manufactured And Supplied By Us Comprises A U-Shaped Horizontal Trough And A Specially Designed Double Helical Ribbon Agitator Rotating Within. Ribbon Blenders Are Based On A Proven Agitator Construction That Provides A Triple Mixing Action Ensuring Fast, Efficient Blending. The Dimensions And Configuration Of The Ribbons Are Carefully Balanced To Provide A Movement Of Material Within The Container That Avoids Dead Spots And Gives Rapid Product Discharge. An Alternate Design Is The Paddle Agitator. The Paddles Are Positioned To Move The Material In Opposing Lateral Directions As Well As Radially. Paddle Design Is Generally Employed Where Friable Material Are Being Blended, And When Batches As Small As 15% Of The Total Capacity Are Going To Be Mixed In The Blender. Depending On The Product

Ribbon Blender Mixer Machine

Ribbon Blender Machine Manufactured And Supplied By Us Comprises A U-Shaped Horizontal Trough And A Specially Designed Double Helical Ribbon Agitator Rotating Within. Ribbon Blenders Are Based On A Proven Agitator Construction That Provides A Triple Mixing Action Ensuring Fast, Efficient Blending. The Dimensions And Configuration Of The Ribbons Are Carefully Balanced To Provide A Movement Of Material Within The Container That Avoids Dead Spots And Gives Rapid Product Discharge. An Alternate Design Is The Paddle Agitator. The Paddles Are Positioned To Move The Material In Opposing Lateral Directions As Well As Radially. Paddle Design Is Generally Employed Where Friable Material Are Being Blended, And When Batches As Small As 15% Of The Total Capacity Are Going To Be Mixed In The Blender. Depending On The Product

Pharmaceutical Ribbon Blender

Ribbon Blender Machine Manufactured And Supplied By Us Comprises A U-Shaped Horizontal Trough And A Specially Designed Double Helical Ribbon Agitator Rotating Within. Ribbon Blenders Are Based On A Proven Agitator Construction That Provides A Triple Mixing Action Ensuring Fast, Efficient Blending. The Dimensions And Configuration Of The Ribbons Are Carefully Balanced To Provide A Movement Of Material Within The Container That Avoids Dead Spots And Gives Rapid Product Discharge. An Alternate Design Is The Paddle Agitator. The Paddles Are Positioned To Move The Material In Opposing Lateral Directions As Well As Radially. Paddle Design Is Generally Employed Where Friable Material Are Being Blended, And When Batches As Small As 15% Of The Total Capacity Are Going To Be Mixed In The Blender. Depending On The Product